Isishwankathelo

I-304 insimbi engenasici luhlobo lwendalo yonke yentsimbi, ukuxhathisa umhlwa kunamandla ngaphezu kwama-200 uchungechunge lwezixhobo zentsimbi, ukuxhathisa ubushushu obuphezulu bungcono, kunokufikelela kwi-1000-1200 degrees.304 insimbi engenasici inokumelana ne-corrosion egqwesileyo kunye nokumelana nomhlwa phakathi kwee-grains.Ukwenzela i-oxidizing yoxinaniso lwe-asidi, ukubilisa i-asidi ye-oxidizing, i-asidi ye-oxidizing ≤ iqondo lokushisa ≤ I-304 insimbi engenasici inokumelana ne-corrosion eyomeleleyo.Ikwanokuxhathisa okulungileyo kwe-corrosion kwisisombululo se-alkali kunye neninzi ye-organic and inorganic acids.

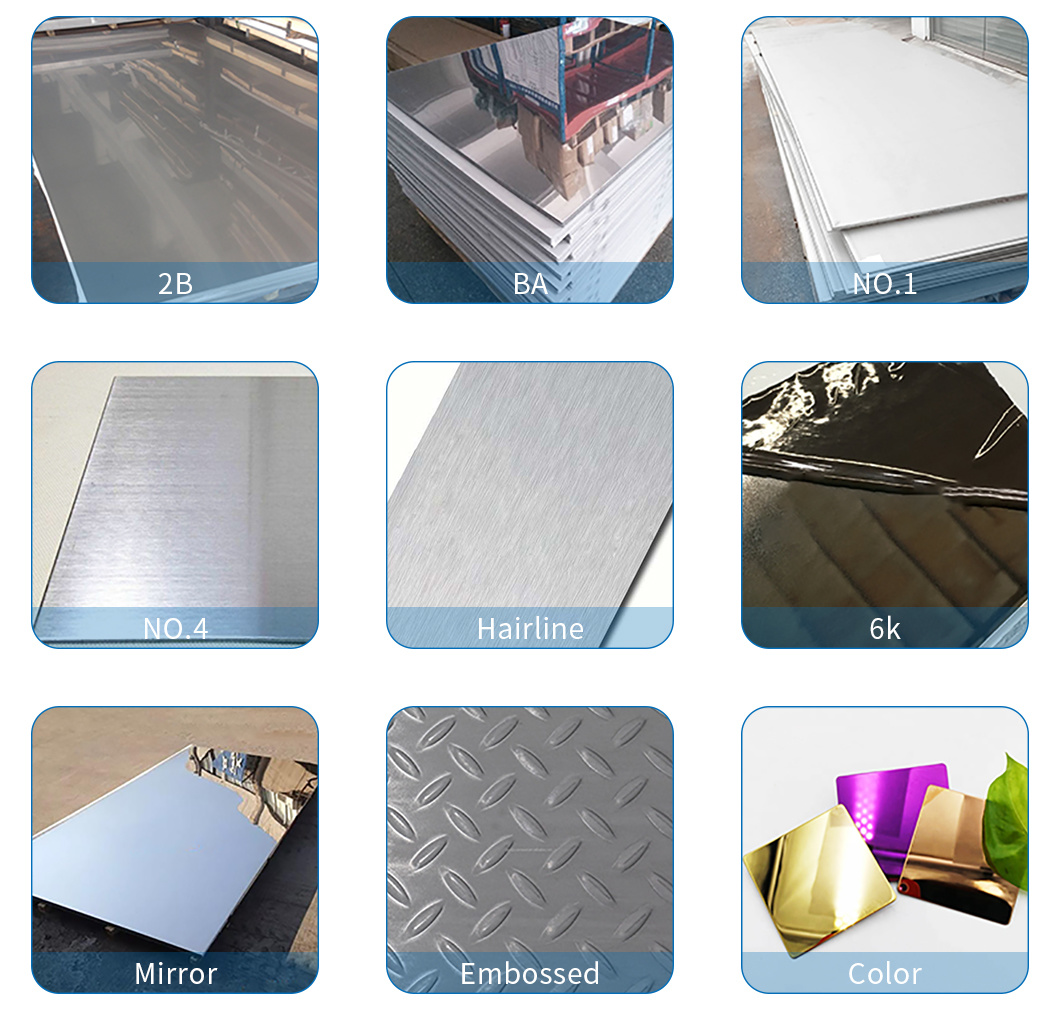

Inkcazo

| Umphezulu Gqiba | Inkcazo |

| 2B | Ukugqitywa okuqaqambileyo, emva kokuqengqeleka okubandayo, ngonyango lobushushu, kunokusetyenziswa ngokuthe ngqo, okanye njengenyathelo lokuqala lokupholisa. |

| 2D | Umphezulu obuthuntu, obangelwa kukuqengqeleka okubandayo kulandela ukuqhotyoshwa nokuhla. Inokufumana umqulu wokugqibela wokukhanya kwimiqulu engapholiswanga. |

| BA | Ukugqitywa kwe-Annealed ekhanyayo efunyenwe ngokufaka izinto phantsi kwe-atmosphere ukuze isikali singaveliswa phezulu. |

| No.1 | Isiphelo esirhabaxa, esibuthuntu, esiphuma ekuqengqelekeni okushushu ukuya kubukhulu obuchaziweyo. Kulandelwa kukuhlanjululwa kunye nokuhla. |

| No.3 | Oku kugqitywa kugudiswa ngu-No.100 ukuya kwi-No.120 abrasive echazwe kwi-JIS R6001. |

| No.4 | Oku kugqitywa kugudiswa ngu-No.150 ukuya kwi-No.180 abrasive echazwe kwi-JIS R6001. |

| Iinwele zeenwele | Ukugqiba okuhle, okukhuselwe yifilimu yePVC ngaphambi kokusetyenziswa, esetyenziswa kwi-kitchenware, |

| 8K isipili | "I-8" kwi-8K ibhekisela kumlinganiselo wamacandelo e-alloy (i-304 insimbi engenasici ibhekisela ikakhulu kumxholo wezinto), "K" ibhekisela kwibakala lokubonisa emva kokupolisha. Umphezulu wesipili we-8K linqanaba lomphezulu wesipili elibonakaliswa yintsimbi ye-nickel alloy steel. |

| Ishicilelwe | Amaphepha ensimbi afakwe kwi-stainless ayizinto eziguquguqukayo ezisetyenziselwa ukudala umphumo wokuhlobisa phezu kwentsimbi. Ziyeyona ndlela ibalaseleyo yeeprojekthi zokwakha, i-splashbacks, imiqondiso, kunye nokunye. Zikhaphukhaphu kakhulu, kwaye zinokubunjwa ukuze zihambelane neenkcukacha zezicelo ezahlukeneyo ezahlukeneyo. |

| Umbala | Intsimbi enemibala yintsimbi egqunywe ngetitanium. Imibala ifunyanwa ngokusebenzisa inkqubo ephuma kwiPVD. Iifom kumphezulu wephepha ngalinye zibonelela ngeendlela ezahlukeneyo zokugquma, ezifana ne-oxides, i-nitrides kunye ne-carbides. |

Iimpawu zeStainless Steel Sheet kunye nePleti

Ezona zinto ziSetyenziswayo zi

1. Ui-sed yokulungisa zonke iintlobo zamalungu aqhelekileyo kunye ne-stamping die;

2.Used njengeendawo ezichanekileyo eziphezulu zentsimbi;

3. Isetyenziswa ngokubanzi kwinkqubo yonyango lokushisa loxinzelelo lwe-annealing ngaphambi kokugoba.

4. Ingasetyenziswa njengesixhobo sokwakha ulwakhiwo loluntu.

7. Ingasetyenziswa kushishino lweemoto.

8. Ingasetyenziswa kushishino lwezixhobo zendlu. Icandelo lamandla enyukliya. Isithuba kunye nenqwelomoya. Indawo yombane kunye nombane. Ishishini koomatshini bonyango. Ishishini lokwakha iinqanawa.

Ukubunjwa kweMichiza yeNtsimbi eSebenzisiweyo eqhelekileyo

| IBanga | C | Si | Mn | P | S | Ni | Cr | Mo | Abanye |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | ― | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | ― | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Isibuko soMbala weShiti leNsimbi eNgatyiwayo kwi-S...

-

316L 2B Ishiti leNtsimbi eCheckered

-

304 Iipleyiti zeNsimbi eziNgenabala eziMbala zokuQotha

-

430 iPhepha leNtsimbi eQiweyo

-

I-SUS304 yePhepha leNtsimbi eQisiweyo

-

201 J1 J3 J5 iPhepha leNsimbi eNgatyiwayo

-

Amashiti eNtsimbi eGcinyiweyo

-

I-PVD ye-316 ye-Coloured Steel Sheet

-

SUS304 BA AMashiti eNtsimbi eNgatyiwayo ngowona mlinganiselo uGqwesileyo

-

SUS316 BA 2B iStainless Steel Sheets Supplier