Ubhedu

Ukusetyenziswa kobhedu kunye nobhedu kwaqala kwiinkulungwane, kwaye namhlanje isetyenziswa kwezinye iitekhnoloji zamva nje kunye nezicelo ngelixa zisasetyenziswa zizicelo zemveli ezinje ngezixhobo zomculo, ii-eyelets zobhedu, amanqaku okuhombisa kunye nezixhobo zempompo kunye nomnyango.

Yenziwe ngantoni iBrass?

I-Brass yi-alloy eyenziwe ngokudibanisa ubhedu kunye ne-zinc ukuvelisa izinto ezinoluhlu olubanzi lwezobunjineli. Ukubunjwa kobhedu kunika isinyithi indawo yokunyibilika efanelekileyo kwizicelo ezininzi, kubandakanywa nokufanelekileyo ukujoyina usebenzisa ubuchule bokuqhayisa. Indawo yokunyibilika yobhedu ingaphantsi kobhedu malunga ne-920 ~ 970 degrees Celsius ngokuxhomekeke kwisixa se-Zn esongezelelweyo. Indawo yokunyibilika yobhedu ingaphantsi kuneyobhedu ngenxa ye-Zn eyongeziweyo. Ingxubevange yobhedu inokwahluka kukwakheka kwe-Zn ukusuka kwi-5% encinci (ebizwa ngokuba yiGilding Metals) ukuya ngaphezulu kwe-40% njengoko isetyenziswa kwiibrasi zomatshini. Igama elingaqhelekanga elisetyenziswayo yibronze yobhedu, apho ezinye izongezo ze-tin zisetyenziswa.

Isetyenziselwa ntoni ubhedu?

Ukubunjwa kobhedu kunye nokongezwa kwe-zinc kwi-copper kuphakamisa amandla kwaye kunika uluhlu lweempawu, okwenza ubhedu luluhlu lwezinto eziphathekayo. Zisetyenziselwa amandla azo, ukuxhathisa umhlwa, inkangeleko kunye nombala, kunye nokusebenza ngokulula kunye nokudibanisa. Isigaba esinye se-alpha brasses, equlathe ukuya kuthi ga kwi-37% ye-Zn, i-ductile kakhulu kwaye kulula ukubanda, i-weld kunye ne-braze. Izigaba ezimbini zealpha-beta iibrasi zihlala zishushu kusetyenzwa.

Ingaba kukho ngaphezu kwesinye isakhiwo sobhedu?

Kukho iibrasi ezininzi ezinemixholo eyahlukeneyo kunye neempawu ezilungiselelwe izicelo ezithile ngezinga lokongezwa kwe-zinc. Amanqanaba asezantsi okongezwa kweZn adla ngokubizwa ngokuba yiGuilding Metal okanye iRed Brass. Ngelixa amanqanaba aphezulu e-Zn angama-alloys afana neCartridge Brass, i-Free Machining Brass, i-Naval Brass. Ezi bras zamva nazo zinokongezwa kwezinye izinto. Ukongezwa kwe-lead kwi-brass kusetyenziswe iminyaka emininzi ukuncedisa ukucwangciswa kwezinto ngokunyanzeliswa kwamanqaku e-chip break. Njengoko umngcipheko kunye nobungozi belothe sele buqatshelwe ukuba kutsha nje kuthatyathelwe indawo ngezinto ezinjengesilicon kunye ne-bismuth ukufezekisa uphawu olufanayo lomatshini. Ezi ngoku zaziwa njengelothe ephantsi okanye iibrasi ezikhokelayo zasimahla.

Ngaba ezinye izinto ezinokongezwa?

Ewe, iimali ezincinci zezinye izinto ezixubekileyo zinokongezwa kubhedu kunye nobhedu. Imizekelo eqhelekileyo ikhokelela kubuchule bomatshini njengoko kukhankanyiwe ngasentla, kodwa kunye ne-arsenic yokumelana nokubola kwi-dezincification, i-tin yamandla kunye nokuhlwa.

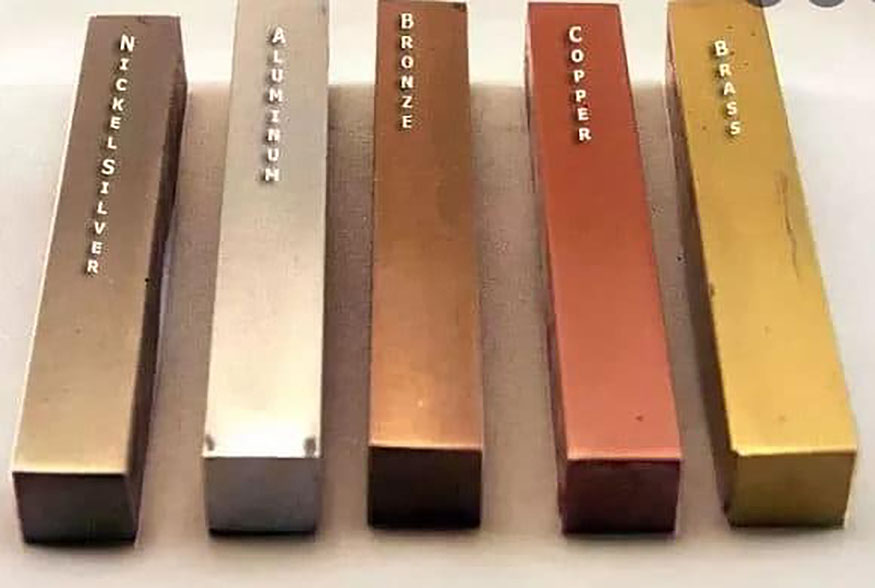

Umbala wobhedu

Njengoko umxholo we-zinc usanda, umbala utshintsha. I-alloys ye-Zn ephantsi inokuthi ifane nobhedu ngombala, ngelixa i-zinc alloys ephezulu ibonakala igolide okanye iphuzi.

Ukuqulunqwa kwemichiza

AS2738.2 -1984 Ezinye iinkcukacha malunga nokulingana

| Inombolo ye-UNS | NJENGOKO No | Igama eliqhelekileyo | Inombolo ye-BSI | Inombolo ye-ISO | Inombolo yeJIS | Ubhedu % | Zinc % | Khokela % | Abanye % |

| C21000 | 210 | 95/5 Gilding Metal | - | CuZn5 | C2100 | 94.0-96.0 | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding Metal | CZ101 | CuZn10 | C2200 | 89.0-91.0 | ~ 10 | < 0.05 | |

| C23000 | 230 | 85/15 Gilding Metal | CZ102 | CuZn15 | C2300 | 84.0-86.0 | ~ 15 | < 0.05 | |

| C24000 | 240 | 80/20 Gilding Metal | CZ103 | CuZn20 | C2400 | 78.5-81.5 | ~ 20 | < 0.05 | |

| C26130 | 259 | 70/30 Arsenical Brass | CZ126 | CuZn30As | ~C4430 | 69.0-71.0 | ~ 30 | < 0.07 | Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 ubhedu | CZ106 | CuZn30 | C2600 | 68.5-71.5 | ~ 30 | < 0.05 | |

| C26800 | 268 | Ubhedu olumthubi (65/35) | CZ107 | CuZn33 | C2680 | 64.0-68.5 | ~ 33 | < 0.15 | |

| C27000 | 270 | 65/35 Wire Brass | CZ107 | CuZn35 | - | 63.0-68.5 | ~ 35 | < 0.10 | |

| C27200 | 272 | 63/37 I-Brass eqhelekileyo | CZ108 | CuZn37 | C2720 | 62.0-65.0 | ~ 37 | < 0.07 | |

| C35600 | 356 | IBras yokukrola, 2% iNkokheli | - | CuZn39Pb2 | C3560 | 59.0-64.5 | ~ 39 | 2.0-3.0 | |

| C37000 | 370 | IBras yokukrola, i-1% yokukhokela | - | CuZn39Pb1 | ~C3710 | 59.0-62.0 | ~ 39 | 0.9-1.4 | |

| C38000 | 380 | Icandelo leBrass | CZ121 | CuZn43Pb3 | - | 55.0-60.0 | ~ 43 | 1.5-3.0 | Aluminiyam 0.10-0.6 |

| C38500 | 385 | I-Brass yokusika yasimahla | CZ121 | CuZn39Pb3 | - | 56.0-60.0 | ~ 39 | 2.5-4.5 |

Iibrasi zihlala zisetyenziselwa ukubonakala kwazo

| Inombolo ye-UNS | Igama eliqhelekileyo | Umbala |

| C11000 | ETP Ubhedu | Pinki ethambileyo |

| C21000 | 95/5 Gilding Metal | Umdaka obomvu |

| C22000 | 90/10 Gilding Metal | Igolide yeBronze |

| C23000 | 85/15 Gilding Metal | Tan Gold |

| C26000 | 70/30 ubhedu | Igolide eluhlaza |

Gilding Metal

I-C22000, i-90/10 yentsimbi ye-Gilding, idibanisa umbala ocebileyo wegolide kunye neyona nhlanganisela yamandla, i-ductility kunye nokumelana nokubola kwe-alloys ye-Cu-Zn. Imozulu iya kumbala wobhedu otyebileyo. Inesakhono esibalaseleyo sokuzoba, kunye nokuxhathisa ekufakeni umhlwa kwimozulu embi kunye nokusingqongileyo kwamanzi. Isetyenziswa kwi-fascias yezakhiwo, ubucwebe, i-ornamental trim, izibambo zomnyango, i-escutcheons, i-hardware yaselwandle.

Iibrasi ezityheli

I-C26000, i-70/30 ye-Brass kunye ne-C26130, i-Arsenical brass, ine-ductility egqwesileyo kunye namandla, kwaye yizona zibhedu ezisetyenziswa kakhulu. Ubhedu lwe-arsenical luqulethe ukongezwa okuncinci kwe-arsenic, ephucula kakhulu ukuxhathisa kwe-corrosion emanzini, kodwa ngenye indlela ifana ngokufanelekileyo. Ezi ngxubevange zinombala ogqamileyo oqaqambileyo owahlukileyo oqhele ukunxulunyaniswa nobhedu. Baneyona ndibaniselwano ilungileyo yamandla kunye ne-ductility kwi-alloys ye-Cu-Zn, idityaniswa nokuxhathisa okuhle kokubola. I-C26000 isetyenziselwa ukwakha, izikhongozeli ezizotyiweyo nezijijekileyo, iitheminali zombane kunye nezihlanganisi, izibambo zomnyango, kunye nehardware ye-plumbers. I-C26130 isetyenziselwa ityhubhu kunye nezixhobo ezidibanisa namanzi, kubandakanywa namanzi okusela.

I-C26800, i-Yellow brass, sisigaba esinye sobhedu se-alpha esinomxholo ophantsi wobhedu. Isetyenziswe apho iipropati zayo ezinzulu zokudweba kunye neendleko eziphantsi zinika inzuzo. Xa amasuntswana adityanisiweyo esigaba se-beta anokuthi enze, ukunciphisa i-ductility kunye nokuxhathisa ukubola.

Iibrasi kunye nezinye izinto

I-C35600 kunye ne-C37000, i-Engraving brass, i-60/40 ye-alpha-beta ye-alpha-beta kunye namanqanaba ahlukeneyo okukhokela adityanisiweyo ukunika iimpawu zomatshini wamahhala. Zisetyenziselwa ngokubanzi iipleyiti ezikroliweyo kunye namacwecwe, i-hardware yabakhi, izixhobo. Akufunekanga isetyenziselwe umsebenzi ofakwe i-asidi, apho i-alpha yesigaba esisodwa kufuneka isetyenziswe.

I-C38000, i-Section brass, i-lead ehamba phambili ye-alpha / beta ngokukhawuleza kunye ne-aluminium encinci, enika umbala oqaqambileyo wegolide. Ukukhokela kunika iimpawu zokusika mahhala. I-C38000 ifumaneka njengeentonga ezikhutshiweyo, iziteshi, iiflethi kunye nee-angles, ezisetyenziswa ngokuqhelekileyo kwi-hardware yabakhi.

I-C38500, ukusika ubhedu, yindlela ephuculwe kakhulu ye-60/40 yobhedu, eneempawu ezibalaseleyo zokusika mahhala. Isetyenziswa ekuveliseni ubuninzi bamacandelo obhedu apho imveliso ephezulu kunye nobomi besixhobo obude bufunekayo, kwaye apho kungasayi kuphinda kufakwe kubanda emva komatshini ofunekayo.

Uluhlu lweeMveliso zobhedu

● Ifom yeMveliso

● Iimveliso ezisicaba ezisongiweyo

● Iintonga ezibunjiweyo, imivalo kunye namacandelo

● Ukwenza isitokhwe kunye neenkohliso

● Iityhubhu ezingenamthungo zokutshintsha ubushushu

● Iityhubhu ezingenamthungo zokupholisa umoya kunye nefriji

● Iityhubhu ezingenamthungo ngeenjongo zobunjineli

● Iingcingo ngeenjongo zobunjineli

● Iingcingo ngeenjongo zombane

Iqela le-Jindalai Steel linikezela ngeemveliso ezahlukeneyo zobhedu ngobukhulu kunye nobungakanani ukuhlangabezana neemfuno zayo nayiphi na iprojekthi. Sikwamkele iipateni zesiko, ubungakanani, imilo, kunye nemibala. Thumela umbuzo wakho kwaye siya kukuvuyela ukubonisana nawe ngobuchule.

UMGAQO WOKUQALA:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

I-IMEYILI:jindalaisteel@gmail.com sales@jindalaisteelgroup.com IWEbhsayithi:www.jindalaisteel.com

Ixesha lokuposa: Dec-19-2022