1. Inyathelo lokuqala: Ukunyibilika

I-aluminiyam yenziwa kusetyenziswa i-electrolysis kwi-industrial scale kunye nezinyibilikisi ze-aluminiyam zidinga amandla amaninzi ukuze zisebenze ngokufanelekileyo. Izinyibilikisi zihlala kufuphi nemizi-mveliso emikhulu yamandla ngenxa yemfuno yazo yamandla. Nakuphi na ukunyuka kweendleko zamandla, okanye inani lamandla afunekayo ukucokisa i-aluminium ukuya kwibakala eliphezulu, kwandisa iindleko zeekhoyili ze-aluminium. Ukongeza, i-aluminium echithiweyo iyahlula kwaye iya kwindawo yokuqokelela. Obu buchule bukwaneemfuno zamandla ezinkulu, ezichaphazela amaxabiso emarike ye-aluminiyam ngokunjalo.

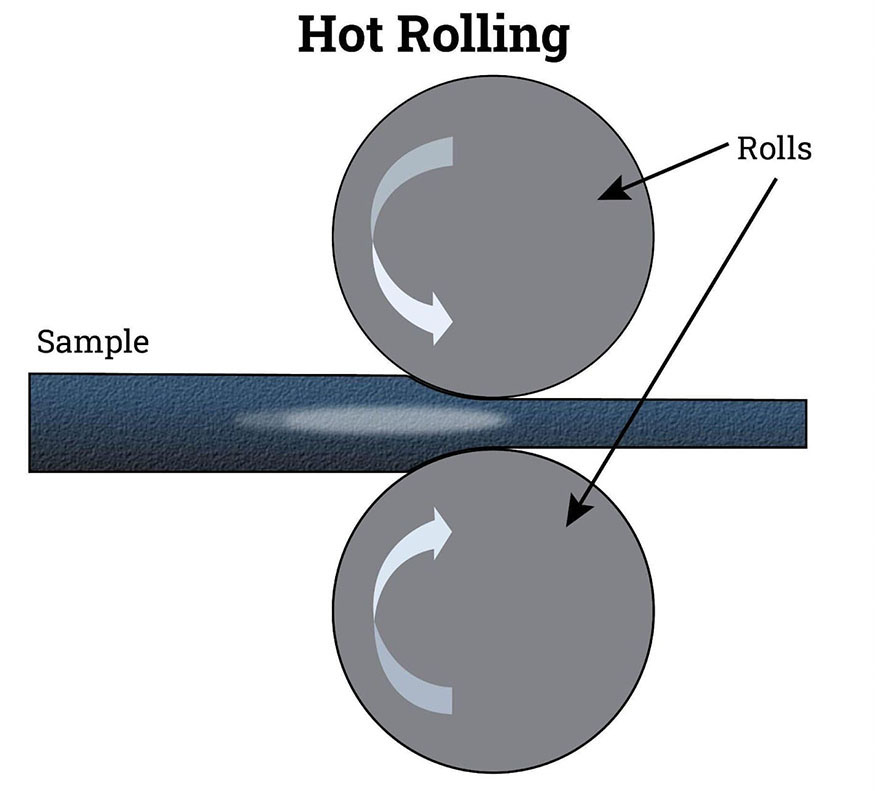

2. Inyathelo lesiBini: Ukuqengqeleka okushushu

Ukuqengqeleka okushushu yenye yeendlela ezisetyenziswa rhoqo ukubhitya i-aluminiyam slab. Kwi-hot rolling, isinyithi sifudunyezwa ngaphezu kwendawo yokubuyisela kwakhona ukuguqula kunye nokuyimisa ngakumbi. Emva koko, esi sitokhwe sesinyithi sigqithiswa kwisibini okanye ngaphezulu kwee-rolls. Oku kwenziwa ukunciphisa ubukhulu, ukwenza ubukhulu bufanane, kunye nokufikelela umgangatho ofunekayo womatshini. Ikhoyili ye-aluminiyam yenziwe ngokucubungula iphepha kwi-1700 degrees Fahrenheit.

Le ndlela inokuvelisa iimilo kunye neeparitha ezifanelekileyo zejometri kunye neempawu zezinto eziphathekayo ngelixa ugcina umthamo wesinyithi rhoqo. Le misebenzi ibalulekile ekuveliseni izinto esele zigqityiwe nezigqityiweyo, ezifana neepleyiti kunye namaphepha. Nangona kunjalo, iimveliso ezigqityiweyo ezigqityiweyo ziyahluka kwiikhoyili ezipholileyo ezibandayo, eziza kuchazwa ngezantsi, kuba zinobunzima obuncinci obufanayo ngenxa yenkunkuma encinci phezu komhlaba.

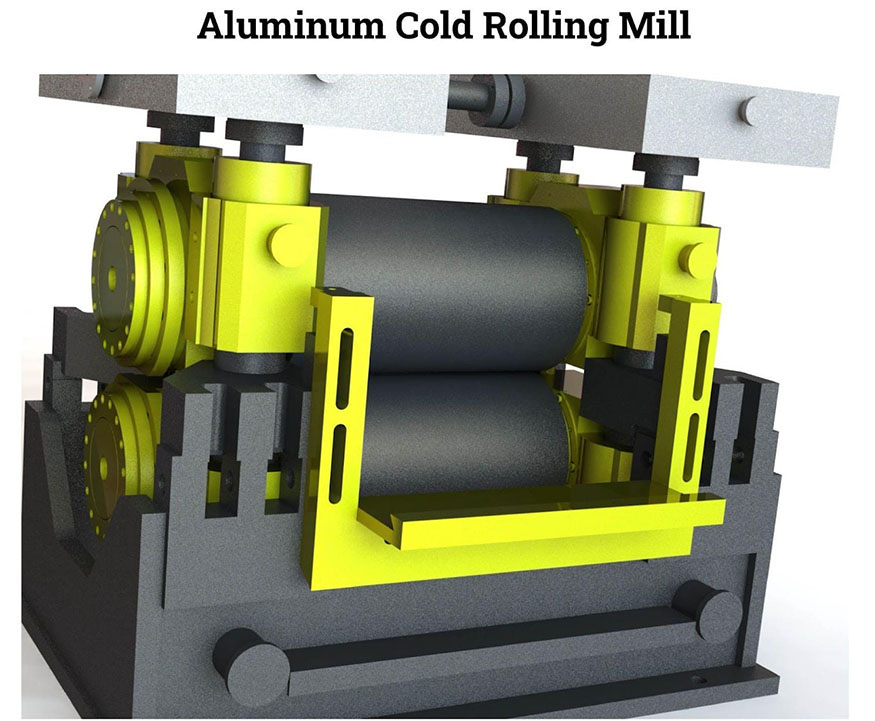

3. Inyathelo lesiThathu: Ukuqengqeleka okubandayo

I-Cold rolling of metal strips yindawo ekhethekileyo yecandelo lesinyithi. Inkqubo "yokuqengqeleka okubandayo" ibandakanya ukubeka i-aluminiyam ngokusebenzisa iiroli kwiqondo lobushushu elisezantsi kunobushushu bayo bokuhlaziya kwakhona. Ukucudisa kunye nokucinezela isinyithi kwandisa amandla ayo okuvelisa kunye nobunzima. Ukuqengqeleka okubandayo kwenzeka kwiqondo lobushushu elisebenza nzima (iqondo lobushushu elingaphantsi kweqondo lobushushu lezinto ezihlaziyiweyo), kwaye ukuqengqeleka okushushu kwenzeka ngentla kobushushu bomsebenzi wokuqina- lo ngumahluko phakathi kokuqengqeleka okushushu kunye nokuqengqeleka okubandayo.

Amashishini amaninzi asebenzisa inkqubo yonyango lwentsimbi eyaziwa ngokuba kukuqengqeleka okubandayo ukuvelisa umcu kunye nentsimbi yentsimbi enegeyiji yokugqibela efunekayo. Imiqulu isoloko ifudunyezwa ukuze incede i-aluminiyam isebenze ngakumbi, kwaye i-lubricant isetyenziselwa ukuthintela umcu we-aluminiyam ukuba ungabambeleli kwimiqulu. Ukuze usebenze kakuhle, intshukumo kunye nobushushu bomqulu bunokutshintshwa. I-aluminium strip, esele iqhutywe eshushu, kunye nezinye iinkqubo, ezibandakanya ukucocwa kunye nokunyanga, zipholile kwiqondo lokushisa ngaphambi kokuba zifakwe kumgca wokusila obandayo kwishishini le-aluminium. I-aluminiyam icocwa ngokuyihlanza ngesicoci kwaye olu nyango luyenza i-coil ye-aluminiyam ibenzima ngokwaneleyo ukumelana nokuqengqeleka okubandayo.

Emva kokuba la manyathelo okulungiselela aqwalaselwe, ii-strips zidlula ngokuphindaphindiweyo ngee-roller, ngokuqhubekayo zilahlekelwa ubukhulu. Iiplani zeeleti zentsimbi ziyaphazamiseka kwaye zivaliwe kuyo yonke inkqubo, nto leyo ebangela ukuba kube nzima, imveliso yokugqibela eyomeleleyo. Ukuqengqeleka okubandayo kuyenye yeendlela ezidumileyo zokuqiniswa kwealuminiyam kuba kunciphisa ubukhulu be-aluminiyam njengoko ityunyuzwa kwaye ityhilwa ngeerola. Indlela yokuqengqeleka ebandayo inokuthoba ubukhulu bekhoyili ye-aluminiyam ukuya kuthi ga kwi-0.15 mm.

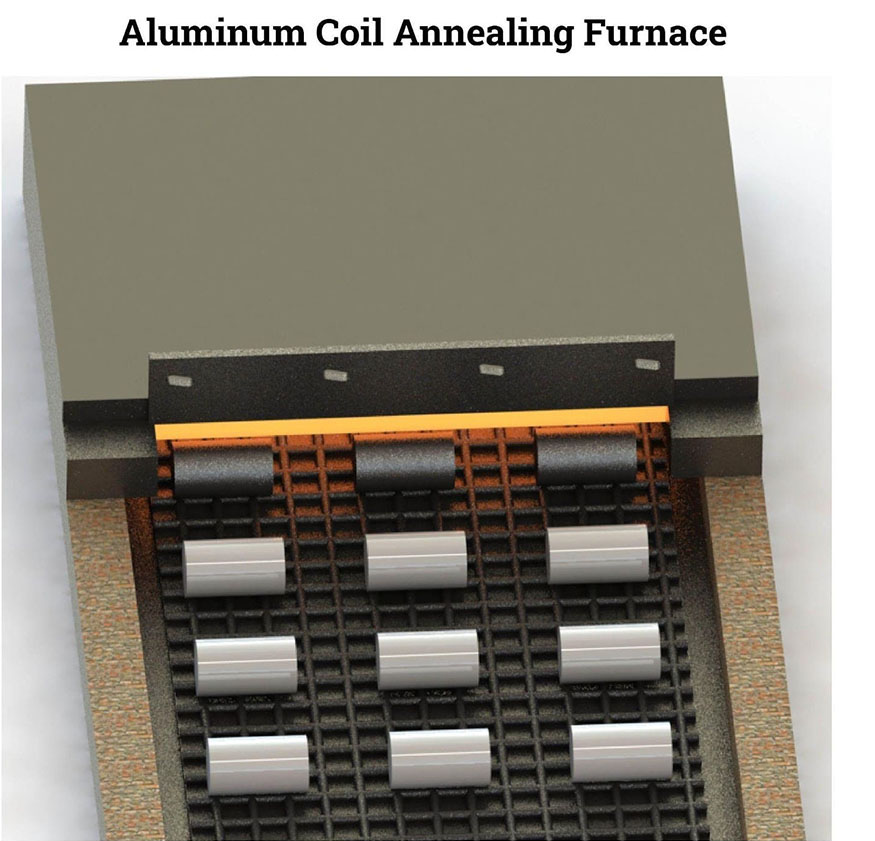

4. Inyathelo leSine: Ukudibanisa

Inkqubo yokuthomalalisa lunyango lobushushu olusetyenziswa ikakhulu ukwenza imathiriyeli ibe lula kwaye ingaqina. Ukuncipha kwe-dislocation kwi-crystal structure yezinto ezifakwe kwi-annealed kubangela oku kutshintshwa kobulukhuni kunye nokuguquguquka. Ukunqanda ukusilela okubuthathaka okanye ukwenza imathiriyeli isebenze ngakumbi kwimisebenzi elandelayo, ukufakwa kwe-anneal kwenziwa rhoqo emva kokuba imathiriyeli yenziwe lukhuni okanye inkqubo yokusebenza ebandayo.

Ngokuseta ngokufanelekileyo ukwakhiwa kweenkozo zekristale, i-annealing ibuyisela iiplani ze-slip kwaye yenza ukubunjwa okungakumbi kwenxalenye ngaphandle kwamandla amaninzi. I-alloy ye-aluminiyam eyenziwe lukhuni kufuneka ifudunyezwe kwiqondo elithile lobushushu phakathi kwe-570 ° F kunye ne-770 ° F kwixesha elimiselweyo, ukusuka malunga nemizuzu engamashumi amathathu ukuya kwiiyure ezintathu. Ubungakanani benxalenye ehlanjululwayo kunye ne-alloy eyenziwe ngokumisela ubushushu kunye neemfuno zexesha, ngokulandelanayo.

I-Anealing iphinda izinzise imilinganiselo yelungu, iphelisa iingxaki eziziswa ziingxaki zangaphakathi, kwaye inciphisa uxinzelelo lwangaphakathi olunokuthi luvele, ngokuyinxenye, ngexesha leenkqubo ezinjengokwenza okubandayo okanye ukuphosa. Ukongeza, iialloyi ze-aluminiyam ezinganyangekiyo ngobushushu nazo zinokukhutshwa ngempumelelo. Ke ngoko, isetyenziswa rhoqo kwisamente, i-extruded, okanye iinxalenye ze-aluminium ezenziweyo.

Isakhono semathiriyeli sokwenziwa siphuculwa ngokufakwa kwe-annering. Ukucinezela okanye ukugoba nzima, izinto ezinqabileyo zinokuba ngumngeni ngaphandle kokubangela ukuphuka. I-Anealing aids ekususeni lo mngcipheko. Ukongeza, ukufakwa kwe-annealing kunokunyusa ukusebenza. Ubuqhophololo obugqithisileyo besixhobo bunokubangela ukuguga okugqithisileyo kwesixhobo. Ngokufakwa kwe-anneal, ukuqina kwesixhobo kunokwehliswa, nto leyo enokunciphisa ukunxiba kwesixhobo. Nakuphi na ukuxinana okushiyekileyo kupheliswa ngokunqanyulwa. Ngokwesiqhelo kungcono ukunciphisa uxinzelelo olushiyekileyo naphi na apho lunokwenzeka khona kuba lunokukhokelela kwiintanda kunye neminye imiba yoomatshini.

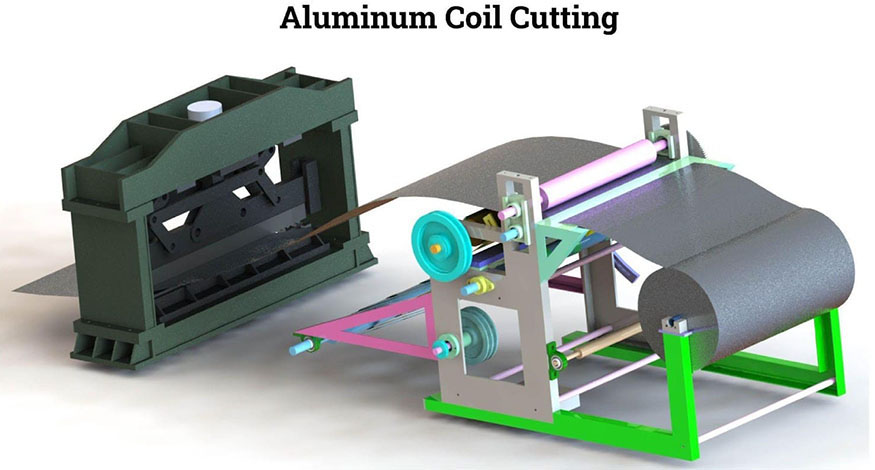

5. Inyathelo lesihlanu: Ukusika kunye nokusika

Iikhoyili ze-aluminiyam zinokuveliswa kumqulu omde kakhulu oqhubekayo. Ukupakisha ikhoyili kwimiqulu emincinci, nangona kunjalo, kufuneka inqunywe. Ukwenza lo msebenzi, imiqulu ye-aluminiyam iqhutywa ngesixhobo sokukrola apho iincakuba ezibukhali ngokumangalisayo zisika ngokuchanekileyo. Kufuneka amandla amaninzi ukwenza lo msebenzi. I-Slitters yahlula umqulu ube ngamaqhekeza amancinci xa amandla asetyenzisiweyo edlula amandla e-aluminiyam.

Ukuqala inkqubo yokuqhawula, i-aluminium ifakwe kwi-uncoiler. Emva koko, idlula kwiseti yeemela ezijikelezayo. Iiblades zibekwe ukuze zifumane eyona ndawo intle yokuqhekeza, kuthathelwa ingqalelo ububanzi obufunwayo kunye nokukhutshwa. Ukuqondisa izinto eziqhekezayo kwi-recoiler, izinto eziphathekayo zityiswa emva koko ngokusebenzisa abahluli. I-aluminiyam ke idityaniswe kwaye isongelwe kwikhoyili ukulungiselela ukuthunyelwa.

Iqela le-Jindalai Steel yiNkampani yeAluminiyam ehamba phambili kunye noMboneleli we-aluminium coil/sheet/plate/strip/pipe/foil. Sinomthengi ovela kwiiPhilippines, eThane, eMexico, eTurkey, ePakistan, e-Oman, e-Israel, e-Egypt, e-Arabhu, eVietnam, eMyanmar, e-Indiya njl njl. Thumela umbuzo wakho kwaye siya kukuvuyela ukubonisana nawe ngobungcali.

UMGAQO WOKUQALA:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

I-IMEYILI:jindalaisteel@gmail.com sales@jindalaisteelgroup.com IWEbhsayithi:www.jindalaisteel.com

Ixesha lokuposa: Dec-19-2022