Isishwankathelo seRebar

Le bar yentsimbi ekhubazekileyo yintsimbi eqhelekileyo yokuqinisa ibha / esetyenziswa kwikhonkrithi eyomeleziweyo kunye nezakhiwo eziqinisiweyo ze-masonry. Yenziwe ngentsimbi epholileyo kwaye inikwe iimbambo zokubambelela okungcono kwi-frictional kwikhonkrithi. Ukuguqulwa kweembambo ngenxa yendima yeembambo, kunye nekhonkrithi inamandla amakhulu okudibanisa, enokumelana ngcono namandla angaphandle. Intsimbi yentsimbi egogekileyo yintonga yentsimbi, intsimbi edityanisiweyo edityanisiweyo, kwaye inokusetyenziswa nakwiminatha yentsimbi. Imilo yeembambo ezinqamlezileyo zi-spiral, herringbone, i-crescent-shaped three. I-dameter ye-deformed ye-deformed reinforced bar ihambelana nobubanzi obubizwa ngokuba yi-circular bar ye-cross-section elinganayo. Ikhonkrithi eyomeleziweyo kuxinzelelo oluphambili lwe-tensile.

Inkcazo yeRebar

| IHRB335 | Ukuqulunqwa kweekhemikhali | C | Mn | Si | S | P | ||||

| 0.17-0.25 | 1.0-1.6 | 0.4-0.8 | 0.045 Max. | 0.045 Max. | ||||||

| IPropati yoomatshini | Unikeze Amandla | Tensile strength | Elongation | |||||||

| ≥335 Mpa | ≥455 Mpa | 17% | ||||||||

| HRB400 | Ukuqulunqwa kweekhemikhali | C | Mn | Si | S | P | ||||

| 0.17-0.25 | 1.2-1.6 | 0.2-0.8 | 0.045 Max | 0.045 Max | ||||||

| IPropati yoomatshini | Unikeze Amandla | Tensile strength | Elongation | |||||||

| ≥400 Mpa | ≥540 Mpa | 16% | ||||||||

| HRB500 | Ukuqulunqwa kweekhemikhali | C | Mn | Si | S | P | ||||

| 0.25 Ubuninzi | 1.6 Ubuninzi | 0.8 Ubuninzi | 0.045 Max. | 0.045 Max | ||||||

| IPropati yoomatshini | Unikeze Amandla | Tensile strength | Elongation | |||||||

| ≥500 Mpa | ≥630 Mpa | 15% | ||||||||

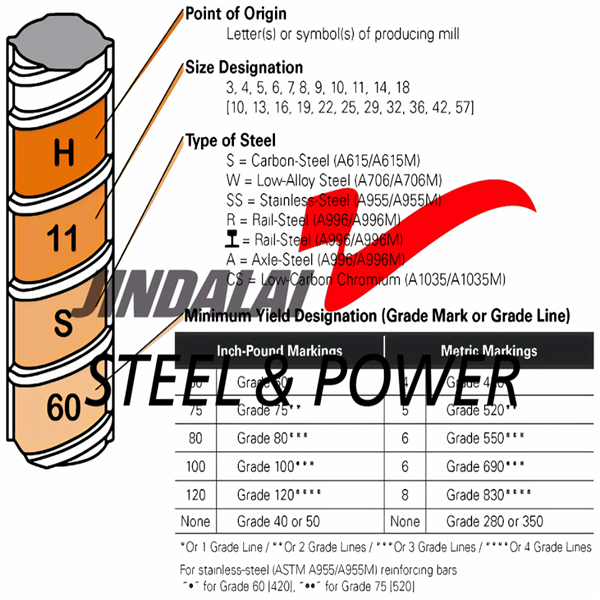

Iintlobo zeeRebar

Ngokuxhomekeke kuhlobo lwemathiriyeli esetyenzisiweyo kwimveliso ye-rebar, iintlobo ezahlukeneyo zee-rebar

l 1. I-European Rebar

I-rebar yaseYurophu yenziwe ngemanganese, eyenza ukuba igobe ngokulula. Ayikulungelanga ukusetyenziswa kwiindawo eziqhelene neemeko zemozulu ezimbi kakhulu okanye iziphumo zejoloji, ezifana neenyikima, iinkanyamba, okanye iinkanyamba. Iindleko zale rebar ziphantsi.

l 2. Carbon Steel Rebar

Njengoko igama limele, yenziwe ngentsimbi yekhabhoni kwaye yaziwa ngokuba yiBlack Bar ngenxa yombala wekhabhoni. I-drawback ephambili yale rebar kukuba i-corrodes, echaphazela kakubi ikhonkrithi kunye nesakhiwo. Umlinganiselo wamandla obunzima obudityaniswa nexabiso lenza i-rebar emnyama ibe lolona khetho lubalaseleyo.

l 3. I-Epoxy-Coated Rebar

I-epoxy-coated rebar yirebar emnyama enedyasi ye-epoxy. Inamandla afanayo okuqina, kodwa iyakwazi ukumelana namaxesha angama-70 ukuya kwi-1,700 ngakumbi kumhlwa. Nangona kunjalo, i-epoxy coating ithambile kakhulu. Umonakalo omkhulu kwi-coating, iyancipha ukumelana nokubola.

l 4. I-Rebar enezingxobo

Irebar eyenziwe ngegalvanized ixhathisa ngokuphindwe kamashumi amane kumhlwa kunerebar emnyama, kodwa kunzima kakhulu ukonakalisa isigqubuthelo serebar eyenziwe ngamagalvanized. Ngaloo ndlela, inexabiso elingaphezulu kune-epoxy-coated rebar. Nangona kunjalo, ixabisa malunga ne-40% ngaphezulu kune-epoxy-coated rebar.

l 5. I-Glass-Fiber-Reinforced-Polymer (GFRP)

I-GFRP yenziwe ngefayibha yekhabhoni. Njengoko yenziwe ngefayibha, ukugoba akuvumelekanga. Iyakwazi ukumelana nokudleka kwaye iyabiza xa ithelekiswa nezinye iibar.

l 6. I-Stainless Steel Rebar

I-rebar yensimbi engenastainless yeyona bar yokuqinisa ebiza kakhulu ekhoyo, malunga namaxesha asibhozo exabiso le-epoxy-coated rebar. Ikwayeyona rebar ilungileyo ekhoyo kwiiprojekthi ezininzi. Nangona kunjalo, ukusebenzisa insimbi engenasici kuzo zonke kodwa ezona meko zikhethekileyo zihlala zigqithise. Kodwa, kwabo banesizathu sokuyisebenzisa, i-stainless steel rebar iphinda-phinda amaxesha angama-1,500 axhathisa ukubola kune-black bar; ixhathisa ngakumbi kumonakalo kunazo naziphi na ezinye iintlobo ezikwaziyo ukudleka okanye ubungqina obunokutshabalalisa okanye isithinteli; kwaye inokugotywa entsimini.