IBanga le-High Steel Carbon Plate

| I-ASTM A283/A283M | I-ASTM A573/A573M | ASME SA36/SA36M |

| ASME SA283/SA283M | ASME SA573/SA573M | EN10025-2 |

| EN10025-3 | EN10025-4 | EN10025-6 |

| I-JIS G3106 | DIN 17100 | DIN 17102 |

| GB/T16270 | GB/T700 | GB/T1591 |

Thatha iA36 Applications njengoMzekelo

Ukusetyenziswa kwe-ASTM A36 Carbon Structural Steel Plate

| Amacandelo oomatshini | Iifreyimu | Ukulungiswa | Ukuthwala iiPlates | Amatanki | Imigqomo | Ukuthwala iiPlates | Forgings |

| Amacwecwe asisiseko | Iigiya | Iikhamera | Sprockets | Iijigs | Iringi | Izempleyithi | Ukulungiswa |

| I-ASTM ye-A36 yeNsimbi yeNsimbi yokuFakwa iinketho | |||||||

| Ukugoba okubandayo | Ukuqulunqa okuthambileyo okuthambileyo | Ukubetha | Umatshini | Ukuwelda | Ukugoba okubandayo | Ukuqulunqa okuthambileyo okuthambileyo | Ukubetha |

Ukubunjwa kweMichiza ye-A36

| I-ASTM A36 Ipleyiti yentsimbi eQhelekileyo | Ukuxutywa kwemichiza | |

| Isiqalelo | umxholo | |

| Carbon, C | 0.25 - 0.290 % | |

| Ubhedu, Cu | 0.20 % | |

| Intsimbi, Fe | 98.0 % | |

| IManganese, uMnu | 1.03 % | |

| Phosphorous, P | 0.040 % | |

| Silicon, Si | 0.280 % | |

| Isulfure, S | 0.050 % | |

Ipropathi ebonakalayo ye-A36

| Impahla Ephathekayo | Metric | Impiriyali |

| Ukuxinana | 7.85 g/cm3 | 0.284 lb/in3 |

IPropati yeMechanical ye-A36

| I-ASTM A36 Ipleyiti yentsimbi eqengqelekayo | ||

| Iipropati zoomatshini | Metric | Impiriyali |

| Amandla okuqina, okugqibelele | 400 - 550 MPa | 58000 - 79800 psi |

| Amandla okuqina, Ukuvunwa | 250 MPa | 36300 psi |

| Ukwandiswa ngexesha lekhefu (kwi-200 mm) | 20.0 % | 20.0 % |

| Ukwandiswa ngexesha lekhefu (kwi-50 mm) | 23.0 % | 23.0 % |

| Imodyuli yeElasticity | 200 GPA | 29000 ksi |

| Ubuninzi beModulus (umzekelo wentsimbi) | 140 GPA | 20300 ksi |

| Poissons Umlinganiselo | 0.260 | 0.260 |

| Shear Modulus | 79.3 GPA | 11500 ksi |

Intsimbi yeCarbon yialloyi ebandakanya intsimbi kunye nekhabhoni. Ezinye izinto ezininzi zivunyelwe kwi-carbon steel, kunye neepesenti eziphantsi eziphezulu. Ezi zinto ziyi-manganese, kunye ne-1.65% ephezulu, i-silicon, ene-0.60% ephezulu, kunye nobhedu, kunye ne-0.60% ephezulu. Ezinye iielementi zinokubakho kubungakanani obuncinci kakhulu ukuba buchaphazele iimpawu zayo.

Kukho iintlobo ezine zentsimbi yekhabhoni

Ngokusekelwe kwisixa sekhabhoni ekhoyo kwi-alloy. Iintsimbi zekhabhoni ezisezantsi zithambile kwaye zenziwe ngokulula ngakumbi, kwaye iintsimbi ezinomxholo ophezulu wekhabhoni zinzima kwaye zomelele, kodwa zincinci, kwaye ziba nzima ngakumbi ukuzisebenzisa kunye nokuwelda. Ngezantsi ziipropati zamabakala e-carbon steel esibonelela ngayo:

● I-Carbon Steel ephantsi-Ukwakhiwa kwe-0.05% -0.25% yekhabhoni kunye nokuya kuthi ga kwi-0.4% yemanganese. Ikwaziwa ngokuba yintsimbi ethambileyo, yimpahla ephantsi ekulula ukuyibumba. Ngelixa ingekho nzima njengentsimbi ephezulu yekhabhoni, ukungcwatywa kwemoto kunokonyusa ukuqina kwayo komphezulu.

● I-Medium Carbon Steel - Ukuqulunqwa kwe-0.29% -0.54% carbon, kunye ne-0.60% -1.65% manganese. Insimbi yekhabhoni ephakathi i-ductile kwaye inamandla, kunye neempawu zokunxiba ixesha elide.

● I-Carbon Steel Ephakamileyo- Ukuqulunqwa kwe-0.55% -0.95% yekhabhoni, kunye ne-0.30% -0.90% ye-manganese. Yomelele kakhulu kwaye ibambe inkumbulo yemilo kakuhle, iyenza ilungele imithombo kunye nocingo.

● Intsimbi yeCarbon ephezulu kakhulu - Ukuqulunqwa kwe-0.96% -2.1% yekhabhoni. Umxholo wayo ophezulu wekhabhoni wenza ukuba ibe yinto eyomeleleyo kakhulu. Ngenxa yobunzima bayo, eli bakala lifuna ukuphathwa okukhethekileyo.

Umzobo weenkcukacha

-

Umzi-mveliso wePleti yentsimbi eqengqelekayo iA36

-

Q345, A36 SS400 Ikhoyili yentsimbi

-

Ipleyiti yentsimbi ye-ASTM A36

-

I-ASTM A653 Z275 Ikhoyili yentsimbi eGatiweyo yaseTshayina Factory

-

Ipleyiti yeS355 yeStructural Steel

-

Ipleyiti yentsimbi yeS355G2 ekude nonxweme

-

Iipleyiti zeS355J2W zeCorten zokuXhobisa iMozulu iipleyiti zentsimbi

-

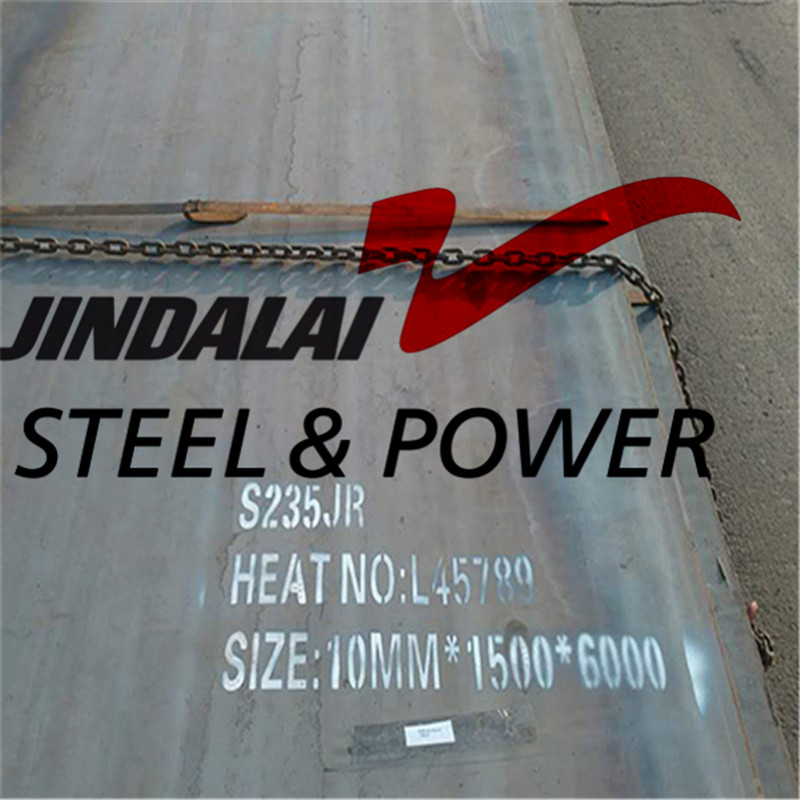

I-S235JR i-Carbon Steel Plates / i-MS Plate

-

I-SS400 Q235 ST37 Ikhoyili yentsimbi eQhelekileyo eQhelekileyo

-

I-Checkered Steel Plate

-

Ipleyiti yeNtsimbi eQhelekileyo eqengqelekayo

-

I-STEEL EMPHAKATHI (MS) Ipleyiti ETSHEKIWEYO

-

Ikhoyili eQhelekileyo eqengqelekayo/uNkszn Checkered Coil/HRC