IiNzuzo ze-AR Steel?

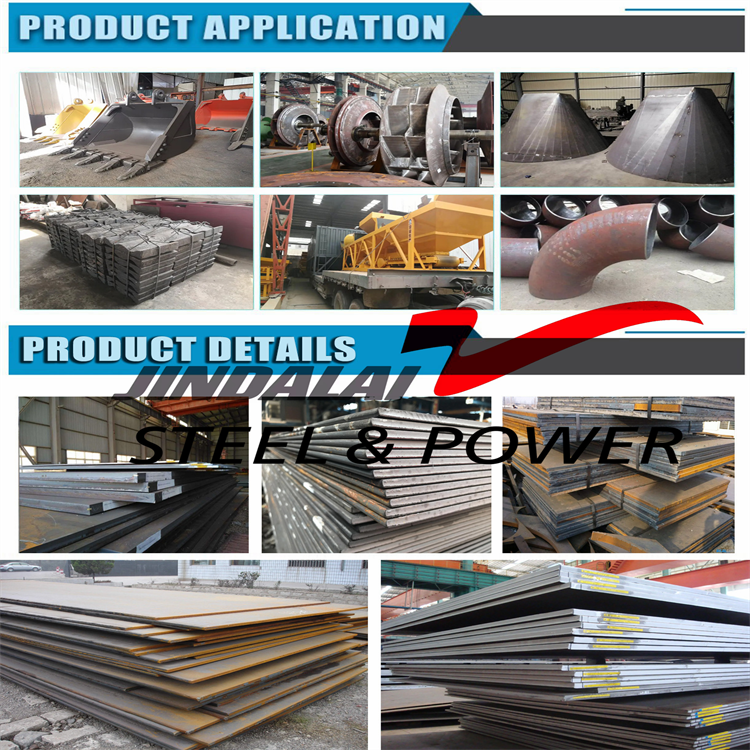

I-Jindalai Steel inikezela nge-AR ipleyiti yensimbi kwimiqulu emikhulu kunye encinci kubaqulunqi kunye nabaqhubi bezityalo abafuna ukwandisa ubomi benkonzo yamacandelo abalulekileyo kunye nokunciphisa ubunzima beyunithi nganye efakwe kwinkonzo. Iinzuzo zokusebenzisa ipleyiti yentsimbi engagugiyo kwizicelo ezibandakanya impembelelo kunye/okanye ukunxibelelana ngokutyibilika ngemathiriyeli ebrayisiyo inkulu kakhulu.

Ipleyiti yentsimbi exhathisa i-abrasion yomelele ngokugqithisileyo kwaye ayinxibi, ikhusela kakuhle kwi-scuffs kunye nemikrwelo. Olu hlobo lwensimbi lusebenza kakuhle kwizicelo ezinzima, kwaye lunika nokuxhatshazwa kwempembelelo. Ukunxiba ipleyiti yentsimbi enganyangekiyo ekugqibeleni iya kunceda ukwandisa ubomi bezicelo zakho kunye nokunciphisa iindleko zakho ekuhambeni kwexesha.

Iinkcukacha ze-AR Steel

| Iinkcukacha | AR400 / 400F | AR450 / 450F | AR450 / 500F |

| Ukuqina (BHN) | 400 (360 imiz.) | 450 (429 imiz) | 500 (450 imiz.) |

| Ikhabhoni (Max) | 0.20 | 0.26 | 0.35 |

| IManganese (UMzu) | 1.60 | 1.35 | 1.60 |

| Phosphorus (Max) | 0.030 | 0.025 | 0.030 |

| Isulfure (Ubukhulu) | 0.030 | 0.005 | 0.030 |

| Isilicon | 0.55 | 0.55 | 0.55 |

| Chromium | 0.40 | 0.55 | 0.80 |

| Okunye | Izinto ezongezelelweyo ze-alloying zinokongezwa ekwandiseni iipropati ezixhathisa i-abrasion. | Izinto ezongezelelweyo ze-alloying zinokongezwa ekwandiseni iipropati ezixhathisa i-abrasion. | Izinto ezongezelelweyo ze-alloying zinokongezwa ekwandiseni iipropati ezixhathisa i-abrasion. |

| Ubungakanani Uluhlu | 3/16″ – 3″ (Ububanzi 72″ – 96″ – 120″) | 3/16″ – 3″ (Ububanzi 72″ – 96″ – 120″) | 1/4″ - 2 1/2″ (Ububanzi 72″ kunye nama-96″) |

Iipropati ze-AR400 NE-AR500 yeePlati zeNsimbi

I-AR400 "i-thru-hardened", i-abrasion resistant, i-alloy wear plate. Uluhlu lobunzima luyi-360 / 440 BHN kunye nobunzima begama le-400 BHN. Ubushushu benkonzo yi-400°F. Le mveliso yepleyiti yenzelwe ukusetyenziswa kwizicelo apho ulungelelwaniso olufanelekileyo lokubumba, ukuqina, ukuqina kunye nokuxhathisa kwe-abrasion kuyadingeka. Iintsimbi ezixhathisa i-abrasion zithengiswa kuluhlu lobunzima kwaye hayi ikhemistri ezinzileyo. Iiyantlukwano ezincinci kwikhemistri zikhona ngokuxhomekeke kwilitye lokusila. Izicelo zinokubandakanya ukusetyenziswa kwemigodi, iikwari, ukuphatha imathiriyeli eninzi, iintsimbi zokusila, kunye nemveliso yepulp & iphepha. Iimveliso zeplate yokunxiba zenzelwe ukusetyenziswa kwelinen; ayenzelwanga ukusetyenziswa njengezakhiwo ezizixhasayo okanye izixhobo zokuphakamisa.

I-AR500 "yi-thru-hardened", i-abrasion resistant, i-alloy wear plate. Uluhlu lobunzima luyi-470 / 540 BHN kunye nobunzima obubizwa ngokuba yi-500 BHN. Le mveliso yepleyiti yenzelwe ukusetyenziswa kwizicelo apho ibhalansi efanelekileyo yempembelelo, ukuqina kunye nokuxhatshazwa kwe-abrasion kuyadingeka. Iintsimbi ezixhathisa i-abrasion zithengiswa kuluhlu lobunzima kwaye hayi ikhemistri ezinzileyo. Ukwahluka okuncinci kwikhemistri kukho ngokuxhomekeke kwilitye elivelisayo. Izicelo zinokubandakanya ukusetyenziswa kwemigodi, iikwari, ukuphatha imathiriyeli eninzi, iintsimbi zokusila, kunye nemveliso yepulp & iphepha. Iimveliso zeplate yokunxiba zenzelwe ukusetyenziswa kwelinen; ayenzelwanga ukusetyenziswa njengezakhiwo ezizixhasayo okanye izixhobo zokuphakamisa.

AR400 VS AR450 VS AR500+ Iipleyiti zentsimbi

Iimill ezahlukeneyo zinokuba "iindlela zokupheka" ezahlukeneyo zentsimbi ye-AR, kodwa izinto eziveliswayo zilawulwa uvavanyo lobunzima - olwaziwa ngokuba yi-Brinell Test - ukumisela udidi oluwela kulo. Iimvavanyo ze-Brinell ezenziwe kwizinto zentsimbi ze-AR zihlala zihlangabezana neenkcukacha ze-ASTM E10 zokuvavanya ubulukhuni bemathiriyeli.

Umahluko wobugcisa phakathi kwe-AR400, i-AR450 kunye ne-AR500 yiNombolo ye-Brinell Hardness (BHN), ebonisa inqanaba lobunzima bezinto eziphathekayo.

I-AR400: 360-440 BHN Ngokuqhelekileyo

I-AR450: 430-480 BHN Ngokuqhelekileyo

I-AR500: 460-544 BHN Ngokuqhelekileyo

I-AR600: 570-625 BHN Ngokuqhelekileyo (engaphantsi kwesiqhelo, kodwa ikhona)